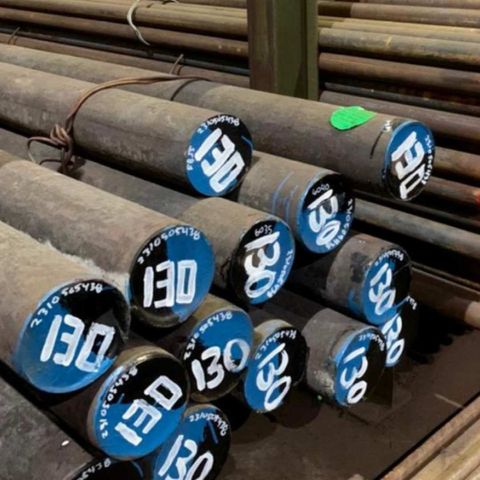

SSA 6582 Nickel Chrome High Tensile Steel, AISI 4340, JIS SCM439, BS EN24, DIN 34CrNiMo6

Price:

R.F.Q.

SSA6582 is a nickel-chromium-molybdenum alloy steel known for its exceptional strength, toughness, and wear resistance. It contains high levels of nickel and chromium, which contribute to its hardenability and high tensile strength. The use of SSA6582 steel is widespread across various industry sectors, particularly in applications demanding higher tensile and yield strength compared to what SSA7225 steel offers. We import from Europe, Japan and China.

Share Product:

Detail

| Trade Name | Technical Delivery Condition | Q & T Hardness | C (%) | Si (%) | Mn (%) | Cr (%) | Mo (%) | Ni (%) |

|---|---|---|---|---|---|---|---|---|

| SSA6582 | Quenched & Tempered | 28 – 32 HRC | 0.30 – 0.38 | ≤ 0.40 | 0.50 – 0.80 | 1.30 – 1.70 | 0.15 – 0.30 | 1.30 – 1.70 |

| Werkstoff | DIN standard | AISI | BS | JIS | SIS |

|---|---|---|---|---|---|

| 1.6582 | 34CrNiMo6 | 4340 | EN110 | SNCM447 | 2541 |

Type of steel and characteristics:

Low alloy chromium, nickel heat treatable steels.

Applications:

Highly stressed components with large cross sections for aircraft, automotive and mechanical engineering such as propeller shafts, connecting rods, gear shafts, crankshafts and landing gear components. Heavy forgings such as rotors, shafts and discs. For economic performance under severe dynamic stress parts must be designed for optimum strength.

Heat Treatment:

Hot Forging - 1050 - 850°C

Normalizing - 850 - 880°C

Annealing - 650 - 700°C

Hardening - 830 - 860°C

Hardness obtainable - 50 – 56 HRC water quenched

Specification

| Keyword |

Catalogue Download